In a significant development affecting the automotive industry, Toyota, one of the world’s largest automobile manufacturers, has announced a temporary production halt at its Czech plant. This decision, reported by Reuters on August 22, 2023, stems from a shortage of critical parts, underlining the challenges that global supply chains continue to face. In this comprehensive article, we delve into the details of Toyota’s production suspension, its implications, and the broader context within which it unfolds.

The Significance of Toyota’s Czech Plant

Toyota’s Czech plant, located in Kolin, is vital to the company’s global manufacturing network. It plays a central role in producing a range of Toyota vehicles, contributing to the automaker’s presence in European markets.

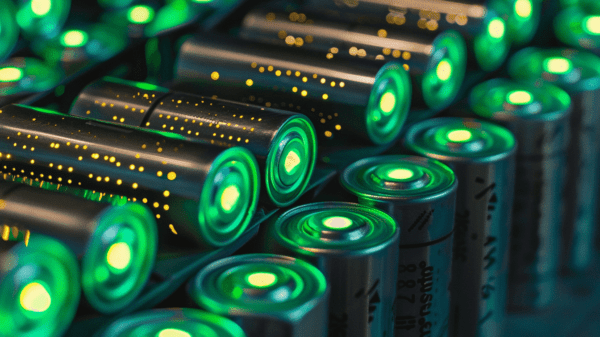

The Parts Shortage Dilemma

The decision to halt production at the Czech plant is a response to a shortage of essential automotive components. Supply chain disruptions, often linked to global logistics challenges and semiconductor shortages, have affected industries worldwide.

Impact on Production and Deliveries

The suspension of production at the Czech plant is expected to impact Toyota’s manufacturing output and could lead to delays in vehicle deliveries to customers. Such disruptions are felt not only by automakers but also by dealers and consumers.

Broader Supply Chain Challenges

Toyota’s production halt symbolizes the broader supply chain challenges companies face in various industries. The COVID-19 pandemic, geopolitical tensions, and the intricacies of global logistics have all contributed to supply chain vulnerabilities.

Efforts to Mitigate Disruptions

Automakers like Toyota are working diligently to mitigate the impact of supply chain disruptions. This includes diversifying suppliers, investing in inventory management, and exploring innovative solutions to maintain production continuity.

Global Automotive Industry Impact

The challenges faced by Toyota are not unique; they resonate throughout the global automotive industry. Automakers across the spectrum are grappling with supply chain disruptions that affect production schedules, pricing, and market dynamics.

The Road Ahead

Companies like Toyota are adapting to new realities as the world navigates the complex terrain of global supply chains. The halt in production serves as a reminder of the need for resilience, adaptability, and innovative solutions in the face of supply chain uncertainties.

Conclusion

In conclusion, Toyota’s decision to halt production at its Czech plant due to a parts shortage reflects the ongoing challenges faced by industries in maintaining stable and efficient supply chains. As global supply chain dynamics evolve, companies like Toyota must adapt and innovate to ensure production continuity and meet customer demand. The impact of such disruptions extends beyond individual businesses, highlighting the interconnectedness of the global economy and the importance of proactive supply chain management.