AI in Manufacturing: Streamlining Production Processes

Discover how AI is streamlining manufacturing processes. Learn how AI is transforming production, reducing costs, and improving quality. Explore the benefits of AI in manufacturing.

KEY TAKEAWAYS

- AI can help streamline and automate manufacturing processes.

- AI-powered solutions can improve efficiency, reduce costs and waste, and increase quality control.

- AI-enabled predictive maintenance solutions can prevent breakdowns and increase production.

- AI-enabled robotics can automate labor-intensive tasks.

- AI can improve product design and development.

The dawn of Artificial Intelligence (AI) has revolutionized the manufacturing industry in ways we never thought possible. From streamlining production processes to optimizing supply chain operations, AI has changed the way we think about how products are made. This article will explore the use of AI in manufacturing and how it is streamlining production processes to improve efficiency and reduce costs. We will look at the various ways AI is being used, from real-time data analysis to predictive maintenance, to make production more efficient and cost-effective. Finally, we will examine the potential of AI in manufacturing and how its use could revolutionize the industry.

Advantages of AI in Manufacturing

Increased Efficiency and Productivity

One of the primary advantages of AI in manufacturing is increased efficiency and productivity. AI-powered machines can work around the clock, with little to no downtime, to complete repetitive tasks more quickly and accurately than humans. This not only boosts productivity but also frees up your employees to focus on more complex and creative tasks that require a human touch.

Improved Quality Control

Another benefit of AI in manufacturing is improved quality control. By using sensors and cameras, AI-powered machines can detect defects and errors in real time, ensuring that only high-quality products make it to market. This not only improves customer satisfaction but also reduces the risk of costly recalls.

Reduced Costs and Waste

AI in manufacturing can also help reduce costs and waste. By analyzing production data in real time, AI-powered machines can identify inefficiencies and waste in the production process, allowing you to make adjustments to improve overall efficiency and reduce waste. This not only saves you money but also helps you become a more environmentally sustainable business.

Predictive Maintenance

Finally, AI in manufacturing can also help with predictive maintenance. By using sensors and data analysis, AI-powered machines can detect potential issues before they become major problems, allowing you to schedule maintenance and repairs before they result in costly downtime. This not only helps keep your production processes running smoothly but also extends the lifespan of your equipment, saving you money in the long run.

Applications of AI in Manufacturing

Robotics and Automation

Robotics and automation are two of the most important applications of AI in manufacturing. AI-powered robots are used to automate repetitive tasks, such as assembly, packaging, and palletizing. AI-enabled robots can detect and respond to changes in their environment, allowing them to complete tasks faster and with greater accuracy. Automation helps manufacturers reduce costs, improve product quality, and increase efficiency.

Predictive Maintenance and Quality Control

AI is also being used to improve the maintenance and quality control processes in manufacturing. AI-based predictive maintenance systems can detect potential problems early and take proactive measures to address them before they become more serious. AI-based quality control systems can detect defects in products and alert human operators, helping to ensure that only the highest quality products are shipped to customers.

Supply Chain Optimization

AI is being used to optimize the supply chain in manufacturing. AI algorithms can be used to analyze data from sources such as inventory records, customer orders, and supplier analytics to identify opportunities to streamline the supply chain. This helps improve efficiency and reduce costs, while also enabling manufacturers to better meet customer demands.

Process Optimization and Workflow Management

AI is also being used to optimize manufacturing processes and workflow. AI-powered systems can monitor production lines and identify areas where production can be improved. AI algorithms can also be used to analyze data to identify bottlenecks and suggest changes that can help improve the efficiency of the production process. By streamlining production processes, AI can help manufacturers reduce costs and increase their output.

Challenges in Implementing AI in Manufacturing

Data collection and analysis

One of the key challenges in implementing AI in manufacturing is data collection and analysis. AI relies on data to learn and make predictions. Therefore, it is crucial to have a large and diverse dataset to train AI algorithms. However, collecting and analyzing data in manufacturing can be challenging due to the complexity of the processes involved. Manufacturing involves a large number of variables, making it difficult to collect and analyze data accurately.

To overcome this challenge, manufacturers need to invest in data collection and analysis tools that can provide real-time insights. IoT sensors and machine learning algorithms can be used to collect and analyze data from various sources such as machines, products, and supply chains. This data can be used to optimize production processes, reduce downtime, and improve product quality.

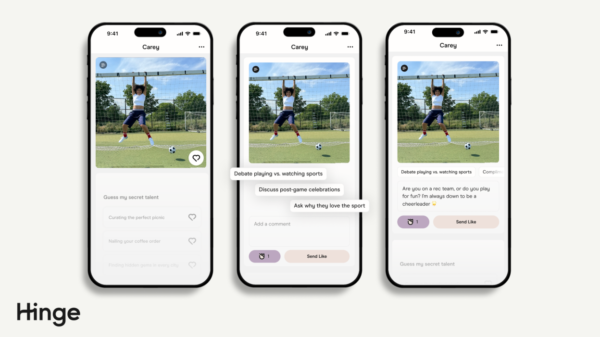

Integration with existing systems

Photo: Geralt

Another challenge in implementing AI in manufacturing is integrating it with existing systems. Manufacturing systems are often complex and may have been developed over many years, making it difficult to incorporate new technologies seamlessly. Manufacturers may also face resistance from employees who are used to working with traditional systems.

To deal with this, manufacturers should adopt a phased approach to implementing AI. They should start with a small pilot project and gradually scale it to larger systems. It is also important to involve employees in the process and provide them with training to ensure a smooth transition to new systems.

Workforce upskilling

Implementing AI in manufacturing requires a highly skilled workforce. AI algorithms require programming skills, and employees need to be trained to work with new technologies. However, many manufacturers struggle to find employees with the required skills.

A solution to this is for manufacturers to invest in workforce upskilling programs. These programs can give employees the necessary skills to work with new technologies. Additionally, manufacturers should partner with educational institutions to develop training programs that can prepare the next generation of workers for the changing demands of the manufacturing industry.

Security and privacy concerns

Implementing AI in manufacturing also raises security and privacy concerns. Manufacturing systems often involve sensitive information such as trade secrets and customer data. Therefore, it is crucial to ensure that AI systems are secure and do not compromise sensitive information.

Manufacturers should implement robust security measures such as data encryption and access controls to overcome this challenge. They should also ensure that AI systems comply with privacy regulations such as GDPR and CCPA. Manufacturers should work with AI vendors that prioritize security and privacy and have a proven track record of implementing secure systems.

Case Studies: Successful Implementation of AI in Manufacturing

Toyota: Predictive Maintenance and Quality Control

Toyota, the world’s leading automaker, has successfully implemented AI-driven predictive maintenance and quality control solutions in its production processes. By using AI to analyze production data, Toyota has been able to identify potential problems before they occur, allowing the company to take preventive action. This has enabled Toyota to reduce production downtime and costs, while also improving product quality. Additionally, AI has enabled Toyota to reduce the number of technicians needed to manually inspect each vehicle, thus further streamlining the production process.

Siemens: Smart Factory Solutions

Siemens, a leading industrial engineering company, has utilized AI-driven solutions to create a “smart factory”. By using AI to monitor and analyze manufacturing data, Siemens has been able to identify and diagnose problems quickly, allowing for faster production times. Additionally, AI has enabled Siemens to optimize its production processes, from tracking materials to creating more efficient assembly lines. This has allowed Siemens to reduce production costs, improve product quality and increase productivity.

Boeing: Digital Twin Technology

Another example of successful AI implementation in manufacturing is Boeing’s utilization of digital twin technology. By using AI-driven simulations, Boeing has been able to create a digital replica of their production processes and use it to identify and address potential issues before they occur. This has allowed Boeing to increase production efficiency, reduce costs and improve product quality. Additionally, digital twin technology has enabled Boeing to reduce the amount of physical testing needed to ensure product safety.

Future of AI in Manufacturing

Future of AI in Manufacturing

Advancements in machine learning and AI technologies have made it possible for manufacturers to leverage the benefits of automation, without sacrificing quality. With AI, businesses can achieve greater productivity, cost savings, and flexibility, which can help them remain competitive in today’s market.

Advancements in Machine Learning and AI Technologies

The integration of AI and machine learning in manufacturing allows machines to learn from past experiences, identify patterns, and make predictions. These advancements have enabled manufacturers to improve their production processes by optimizing operations, predicting maintenance needs, and identifying quality issues before they arise.

For example, AI-powered predictive maintenance systems can detect and address potential machine issues before they become major problems, thereby reducing unplanned downtime and ensuring that production processes remain uninterrupted. Similarly, the use of AI-powered computer vision systems can help manufacturers detect defects and quality issues in real-time, thereby reducing product waste and improving overall quality.

Increased Adoption and Implementation

As more manufacturers begin to recognize the benefits of AI, we can expect to see increased adoption and implementation of these technologies in the manufacturing industry. In fact, according to a recent report by the Boston Consulting Group, the adoption of AI in manufacturing is expected to increase significantly in the coming years, with an estimated $500 billion in annual value potential by 2025.

This trend is also reflected in the investments made by major corporations such as NVIDIA, Apple, and Google, who are leading investors in AI-powered edge computing, which is crucial in solving computing challenges and integrating more devices into the Internet of Things (IoT).

Potential Impact on the Workforce

While the implementation of AI in manufacturing has many benefits, it also raises concerns about the potential impact on the workforce. As machines become more intelligent and automation replaces some manual labor, it is important to consider the implications for workers.

However, it is important to note that AI is not meant to replace human workers entirely. Instead, AI can be used to enhance human capabilities and enable workers to perform their jobs more efficiently and effectively. For example, AI-powered cobots (collaborative robots) can work alongside human workers, assisting them in completing tasks and improving overall productivity.

Final Thoughts

AI has revolutionized the manufacturing industry by streamlining production processes, increasing efficiency, and reducing costs. From predictive maintenance to automated quality control, AI-driven technologies are being used in a variety of ways to optimize the production process. Companies that have implemented AI have seen a significant increase in production output as well as a decrease in errors and waste. With the ability to constantly monitor and track data, AI has enabled manufacturers to quickly detect errors and take corrective action. AI has improved the quality and efficiency of the manufacturing process, while at the same time reducing costs and increasing profits. As AI continues to evolve, the possibilities of how it can be used to optimize the production process are endless. AI has revolutionized the manufacturing industry, streamlining production processes and paving the way for a more efficient future.