Overview

Automation and manufacturing are being revolutionized with the aid of AI and robotics, that are growing previously unheard-of possibilities for accuracy, performance, and creativity. Artificial intelligence, or AI, is the term used to explain the imitation of human mind in robots with thought and mastering skills. The design, constructing, and operation of robots to perform obligations usually performed by way of people is known as robotics. When combined, these technologies are revolutionizing the industrial region by using bringing down prices, growing speed, and improving reliability. This article examines the development of synthetic intelligence (AI) and robotics in the course of history, as well as their present uses, blessings, difficulties, and potentialities.

The Historical Background of Robotics and AI in Manufacturing

Revolutionizing Production with Robot

The introduction of assembly strains, in particular by way of Henry Ford, marked the start of the economic automation adventure within the early 1900s. Because they have been mechanical, those early computerized devices wished human supervision. With the arrival of computers and virtual technology within the 1970s, a primary advancement was made feasible by way of elevated automation. Robots had been used at the manufacturing unit floor by using the Eighties, frequently for repetitive paintings. The actual revolution commenced in the twenty first century while synthetic intelligence (AI) was included and allowed robots to accomplish obligations with extra accuracy and versatility.

Robotics and AI’s Current Uses in Manufacturing

Automation in Production Lines

Robots are utilized in contemporary meeting lines to do operations consisting of welding, portray, assembly, and packing. With their fantastic precision and capacity to paintings nonstop, these robots can extensively cut down on mistakes and manufacturing delays. For instance, robotic fingers are used inside the car assembly method by using Ford and General Motors to make sure uniform exceptional and productiveness.

Artificial Intelligence for Quality Management

Artificial intelligence (AI) technology are used in exceptional manipulate to find flaws that aren’t obvious to the naked eye. These structures have a look at statistics and images from production strains the use of gadget mastering algorithms to spot irregularities and assure that simplest advanced goods are despatched onto the marketplace. AI-driven best manipulate solutions had been followed through corporations consisting of Unilever and Coca-Cola to improve product reliability.

Maintenance That Is Predictive

Predictive protection structures with AI competencies song system in real time and foresee problems before they manifest. By taking proactive measures to restoration problems, this method reduces preservation fees and downtime. For instance, GE’s Predix platform leverages AI to forecast industrial equipment maintenance wishes, maximizing working efficiency.

Self-governing Material Processing

The way that substances are handled in manufacturing is changing because of self sufficient robots. Without the want for human assistance, those robots flow items and substances for the duration of the manufacturing unit ground way to their sensors and navigation systems. One splendid instance of how robots effectively take care of inventory and order achievement is Amazon’s deployment of Kiva robots in their warehouses.

AI and Robotics’ Advantages for Manufacturing

Enhanced Productivity and Efficiency

Robotics and synthetic intelligence (AI) automate complicated and repetitive operations, substantially increasing manufacturing productivity. Robots are extra efficient due to the fact they could paintings nonstop with out getting worn-out. AI systems streamline workflows and production schedules to provide maximum output with the least amount of waste.

Improved Accuracy and Focus

Robotic accuracy and artificial intelligence’s analytical strength combine to supply always excellent merchandise. Artificial intelligence (AI) powered high-quality control systems guarantee that flaws are located and glued quick, reducing the frequency of faulty goods. In sectors wherein pleasant is critical, which include aerospace and medical device manufacture, this precision is crucial.

Lowering of Expenses

Robotics and AI will have hefty upfront expenses, but they are able to provide great lengthy-time period cost reductions. Automation boosts general manufacturing performance, avoids waste, and lowers exertions costs. In order to reduce logistical fees and transport times and pass production closer to consumer markets, corporations which include Adidas have adopted automation.

Enhanced Security

Robotics and artificial intelligence boom worker safety through assuming risky obligations. Robots reduce place of work accidents by way of managing unsafe chemical compounds and wearing out excessive-hazard tasks. The use of synthetic intelligence (AI) into monitoring systems augments safety by way of looking ahead to and heading off viable risks.

Difficulties in Putting AI and Robotics to Use

Excessive Outlay at First

Robotics and AI implementation call for massive capital costs. For small and medium-sized groups, the value of sophisticated robotics, AI software program, and the desired infrastructure may be a hurdle. Nonetheless, the preliminary outlay is regularly justified by means of the long-time period blessings.

Combining with Current Systems

It is probably hard to integrate new robotic and AI technology with cutting-edge production processes. Careful planning, compatibility checking out, and once in a while a complete revamp of the contemporary structures are necessary. In order to save you production disruptions, clean integration ought to be ensured.

Insufficient Skilled Workforce

The implementation of robotics and AI requires a body of workers with the vital skills to operate and maintain those structures. Workers with revel in in robotics, AI, and statistics analytics are in greater call for. It is vital that this capabilities gap be filled as a way to efficaciously observe state-of-the-art production technology.

Concerns approximately Ethics and Regulations

The software of robotics and AI affords moral and prison concerns approximately records privateness, employment displacement, and adherence to safety guidelines. Manufacturers want to address those troubles to guarantee that technology is used responsibly and legally. Sustainable growth necessitates the established order of ethical principles and clean legal guidelines.

Cutting-Edge Technologies Spewing the Revolution

Deep Learning and Machine Learning

The core of AI advancements in manufacturing is device studying and deep getting to know. Systems are capable of analyze from statistics way to these technology, which steadily improves their performance. Machine getting to know algorithms, for instance, decorate deliver chain control by using forecasting demand and editing stock stages accurately.

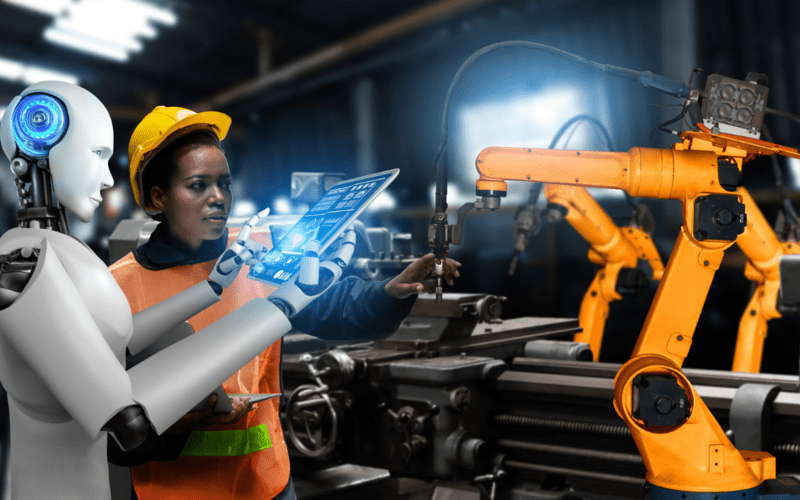

Cobots, or collaborative robots

Collaborative robots are intended to assist human people, growing efficiency and safety. Cobots, in comparison to common robots, have AI and sensors to permit for safe human-robot interaction. Their versatility and performance are positioned to apply in jobs like high-quality inspection, packing, and meeting.

The Internet of Things

Real-time information transmission and analysis are made viable with the aid of the IoT’s ability to attach machines, sensors, and gadgets. IoT enables clever factories in manufacturing, wherein self reliant gadget coordination and conversation are viable. The overall operating intelligence, predictive preservation, and efficiency are all advanced by this hyperlink.

Digital Duplicates

They are simulation and analysis gear that use virtualized variations of actual-global structures. Digital twins in production allow manufacturing procedure improvement and real-time monitoring. Without interfering with ongoing commercial enterprise sports, they resource in locating inefficiencies, forecasting screw ups, and checking out novel processes.

Case Studies in Manufacturing Using Robotics and AI

The Gigafactories of Tesla

Robotics and AI integration in production are best confirmed by means of Tesla’s Gigafactories. Advanced robotics is utilized in these industries to perform activities like automobile assembly and battery manufacturing. Tesla has been capable of grow manufacturing quickly due to the fact AI structures manage inventories and optimize production schedules.

The Smart Factories of BMW

Robotics and synthetic intelligence are utilized in BMW’s smart factories to increase manufacturing performance and flexibility. Assembly and great control are treated via robots, even as process optimization is performed with the aid of AI structures studying manufacturing statistics. BMW is able to adapt manufacturing to marketplace traits and consumer expectations due to the fact to this integration.

Siemens’ Electronics Plant in Amberg

The digital production benchmark for Siemens is their manufacturing facility in Amberg. The factory builds a quite automatic and networked production environment by using making use of AI and IoT. While IoT gadgets reveal and adjust manufacturing in real-time to gain nearly ideal product exceptional and performance, AI algorithms forecast renovation wishes.

Robotics and AI’s Role in Manufacturing Futures

New Developments in Trends and Technologies

Developments in AI, robotics, and associated fields will influence production within the destiny. Manufacturing procedures might be redefined by means of trends like AI-driven layout, self-using manufacturing lines, and sophisticated human-gadget collaboration. Capabilities will be further stronger via innovations like 5G connectivity and quantum computing.

Possibility of New Business Models

New commercial enterprise models, such mass customisation and on-call for manufacturing, are made possible with the aid of AI and robotics. These fashions keep efficiency even as enabling companies to offer custom designed gadgets. Reconfiguring manufacturing traces speedy will permit companies to react quickly to changes inside the marketplace.

Extended Economic and Social Repercussions

There may be good sized societal and monetary consequences from the huge use of robotics and AI. Although these technology have the capability to increase productivity and financial boom, in addition they run the risk of displacing workers and necessitating sizeable workforce retraining. Businesses and policymakers need to paintings collectively to clear up those troubles and guarantee inclusive growth

Key Takeaway

Manufacturing is undergoing a transformation thanks to the combination of AI and robotics, which has significantly improved productivity, quality, and safety. Although these technologies make production more accurate and economical, they also bring with them a number of difficulties with regard to worker skills, system integration, investment, and ethical issues. This shift is being driven by important new technologies like digital twins, IoT, collaborative robotics, and machine learning.

Future developments in trends and technology hold the potential to significantly alter the manufacturing sector by bringing in new business models and having a significant impact on the economy and society. The Tesla, BMW, and Siemens case studies demonstrate how well-known businesses are utilizing these technologies to transform their manufacturing processes.

In an increasingly automated environment, manufacturers need to deliberately address the obstacles and capitalize on the advantages of robots and artificial intelligence to stay competitive. It’s an exciting moment to be in the manufacturing business because of the enormous potential these technologies have to spur growth and innovation. Businesses may successfully and sustainably handle this transition by remaining educated and proactive.

Final Thoughts Regarding the Future

The direction that robotics and AI are taking in the manufacturing sector points to a highly flexible, intelligent, and efficient production environment in the future. The distinctions between digital and physical production will become increasingly hazy as technology develops, opening up hitherto unheard-of levels of potential and integration. Businesses who adapt to these changes and make the required investments in infrastructure and talent will be well-positioned to take the lead in this new manufacturing era.

It is imperative that policymakers, educators, and industry leaders collaborate to tackle ethical and workforce issues, guaranteeing that the advantages of this technology revolution be distributed fairly. Robotics and artificial intelligence will surely continue to revolutionize manufacturing with careful application and ongoing innovation, fostering advancement and wealth in the years to come.

FAQ

1. What are the principal advantages of robotics and AI in the manufacturing sector?

A: Better safety, lower costs, higher quality, and increased efficiency.

2. What difficulties do producers have integrating automation and AI?

A: Expensive initial outlay, compatibility with current systems, lack of qualified labor, and moral dilemmas.

3. What distinguishes collaborative robots from conventional robots?**

A: Cobots are made to safely collaborate with people, increasing efficiency and adaptability.

4. What part does IoT play in manufacturing?**A: The Internet of Things (IoT) links equipment, facilitating real-time data sharing and intelligent manufacturing processes.

5. What are “digital twins,” and how are they applied in the manufacturing industry?

A: Digital twins are virtual versions of real systems that are utilized in manufacturing processes for monitoring, modeling, and optimization. They make it possible to track production systems in real time, do predictive maintenance, and try new tactics without causing any physical disturbances.