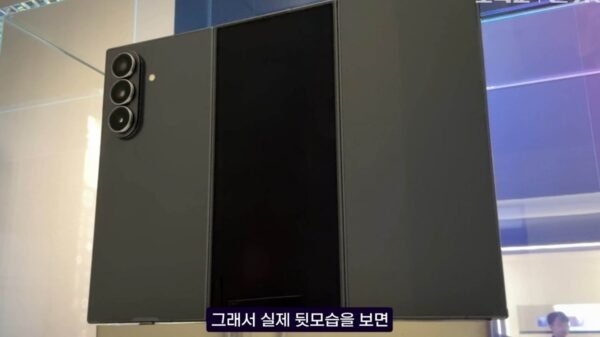

Look out industrial manufacturing, there’s a new kid on the block: It’s the Metal Jet Printer, and HP says it will completely change the way industrial manufacturing is done.

HP hopes this printer will serve as a faster, more effective, and less costly variation to the more traditional industrial method of mass-manufacturing small metallic parts – using a precision high-heat laser to harden specific parts of a sheet of powdered metal.

HP’s printer applies the same principles of 3D printing – layering sheets and tiny, thin sheets of a material atop one another to create a 3D object. The difference here is that HP has figured out how to accomplish this task using metal instead of plastic, and has also accelerated the speed to ludicrous levels – the Metal Jet, according to a GIF on Cnet, can print tiny metallic parts at similar speeds to the rate at which your office printer shoots out regular paper, if not faster.

According to HP’s own description of the printer from its product page, this printer will be available for “less than $399,000”, a figure which HP refers to as a ‘low cost’. That settles it – this device definitely isn’t for your average consumer, but in terms of industrial metal printing and cutting devices, that ‘low cost’ promise does hold up – Industrial printers with an intended function similar to the Metal Jet can cost up to $750,000.

But, if the printer is really as effective and revolutionary as HP is making it seem – a question still stands: Why didn’t they charge more? This looks like a massive step forward for industry leaders coming from HP, and HP easily could have charged double their ~$400,000 asking price and still sold a grand number of these devices, considering their ability to construct parts up to 50 times as quickly as competing machines.

The answer lies in their reliance on the “razor and blades” business model that HP – and their signature printers – have been using since the onset of their massive popularity.

HP’s product page for the printer goes into grand detail over its price and efficiency, promising business and factory owners that they will save large amounts of money through business with HP. However, the company fails to highlight the availability and prices of the metal sheets that the device doubtlessly needs to operate properly. Metal sheets that, in all likelihood, are manufactured only by HP themselves, since this Metal Jet printer is a brand new technology that has never been seen before in the industrial world.

This exclusivity will allow HP to charge much higher prices for the metal sheets than do most industrial manufacturing machines do for powdered metal, since powdered metal is much simpler to produce and can be produced by many companies, thus creating competition that results in lowered prices for consumers.

Thus, HP plans to sell its Metal Jet printers much like the sale of a subscription service – the initial cost is low, but the upkeep is constant, and the purchase of new sheets of ink may turn out to be more costly in the long run.

However, this probably doesn’t matter to many of the businesses that will be using them – the boost in efficiency will provide them with a massive increase in general productivity, which will allow them to expand far past their previous limitations. If it ends up costing more in the long run, many businesses using the printers may find the cost justified due to the large increase in sales and the amount of expansion they have been able to afford due to boosted productivity.

Although HP could most likely produce commercial 3D printers as well, they may focus less on that due to commercial 3D printing being seen as less of an ‘essential’ service, making their signature razer and blades business model less effective.

Larry

October 23, 2018 at 3:43 pm

This is really interesting, but have you heard of a guy named Bill Masters? I recently read an article on OZY about how Masters developed the first 3D printing patent – then lost it. Anyone know anything about this? Here it is for reference: http://www.ozy.com/flashback/and-he-could-have-been-the-father-of-3d-printing/81198#.WeXu6REalHI.twitter