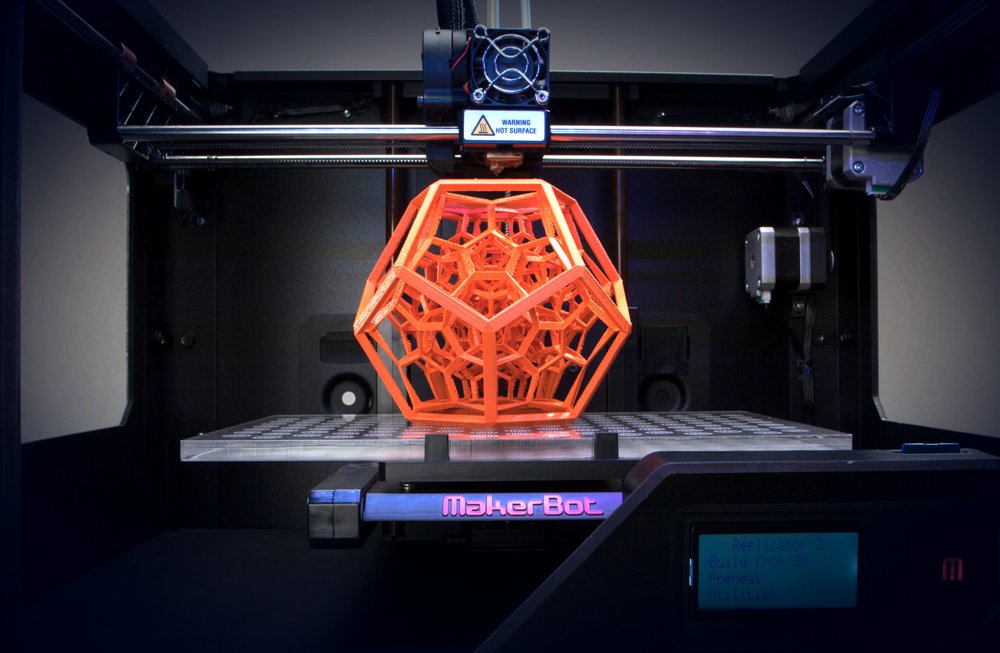

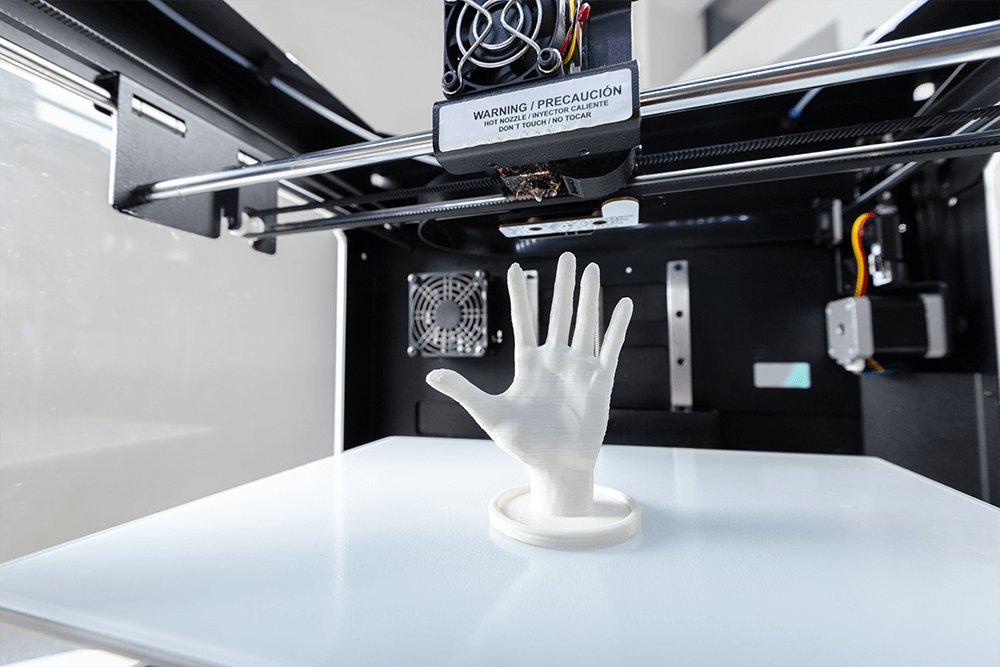

The Latest Developments in 3D Printing for 2023

The use of additive manufacturing (AM) is expanding at an exponential rate every year. What can you therefore anticipate for 2023? Find out which four themes we believe will propel AM ahead over the next 12 months.

The use of additive manufacturing in manufacturing has grown significantly during the last thirty years. Although its flexibility and adaptability offer a lot of value, it has also been separated from traditional manufacturing methods for a significant portion of that period. These barriers are, however, gradually falling down as the two worlds start to converge.

This has a lot of ramifications.

The 3D printing trends that will influence our industry in the next months are presented by Materialise each year. We think that by 2023, these four developments will be crucial in removing any remaining obstacles to integrating technology into industrial production processes. As follows:

The expansion of dispersed, smart manufacturing a goal of cutting costs Workflow automation replaces process automation. Data integrity and security are increasingly important.

Companies may expand their 3D printing operations into volume production and accelerate 3D printing adoption by solving these issues.

It’s time to examine the three-dimensional printing trends influencing the market. With continued supply chain interruptions, the crisis in Ukraine, and the resulting increase in both energy and raw material costs, last year was once again difficult. It has shown that, in order to meet these issues, it is still crucial to lower prices and strengthen supply chains, and that the use of 3D printing may be quite helpful in doing so. Here are 5 themes that we believe will have a significant influence on the 3D printing market in 2019 and beyond.

Greater variety of 3D printing applications as a result of technical maturation

Photo:

Parametric Architecture

The technology will become more widely used in sectors including healthcare, industry, agriculture, and transportation as more revolutionary materials are developed. Businesses are rapidly moving away from experimentation and toward volume production with their additive manufacturing techniques. Companies utilise 3D printing in this way to fill the gap between demand and supply or as a substitute for conventional production (also known as “bridge manufacturing”). The technology is allowing the quick availability of crucial components at times when supply chain disruptions are happening and specific components and raw materials have enormous lead periods. The best option is additive manufacturing for both production ramp-up and replacement parts for older models. In 2023, service bureaus and 3D printing platforms will be crucial to corporate growth and meeting all application requirements. They lessen the danger and expense of installing one’s own infrastructure and make it simple to switch from one kind of substance and technology to another.

Growing importance of the digital supply chain

The need for simplified operations is being driven by the rising popularity of 3D printing, which will increase efficiency and lower costs. More mechanised and integrated AM processes will be popular in 2023. They link all market participants involved in 3D printing, including software providers, clients of print farms, and experts in post-processing and material science. They integrate production and supply chain.

The use of 3D printing component identification software to swiftly assess the 3D printability of a huge list of parts will become more widespread. Additionally, the use of digital warehouse systems will help businesses manage their components more effectively during their entire lifespan. On the one hand, businesses may stop storage and begin manufacturing as needed. However, it also gives them the option to directly purchase items via a linked or integrated ordering system and have them made locally. Overall, an additive manufacturing-based digital supply chain will result in much more transparency, sustainability, flexibility, and efficiency.

Quality control is the cornerstone of commercial 3D printing.

The utilisation of secure procedures, approved materials, and appropriate technology is a new 3D printing development that goes along with industrial additive manufacturing. Each item produced with 3D printing has to adhere to the same standards for quality and process repeatability.

Photo:

Bernard Marr

For this reason, Replique included the QA module RSure to our end-to-end 3D printing platform. The technology enables original equipment manufacturers (OEMs) to digitally specify quality standards and an inspection procedure (such as measurements, picture documentation, etc.) that 3D printing service providers must carry out before sending the component. Each manufactured part’s manufacturing data is centrally saved on the platform as a “digital twin” component. This makes it possible to utilise a decentralised 3D printing platform on an industrial scale and to record parts seamlessly.

We furthermore see a rising tendency to apply AI to manage digital manufacturing in order to enhance the stability of AM operations. To prevent and correct mistakes, allow dependability and repeatability of AM operations, and monitor, gather, and evaluate machine data in-situ, AI will be used.

Environmentally friendly additive manufacturing

The year 2023 and any new ideas that emerge will be shaped by the drive toward greater sustainability. By dramatically lowering the CO2 footprint of components in multiple ways, AM will become a more prevalent technology to meet sustainability objectives.

Avoid overproduction by just manufacturing the pieces that are required.

There is no need to discard things because parts are missing.

lessening of transportation initiatives

As additional use cases are created expressly for 3D printing over the next several years, the ability to redesign components to be thinner and more durable will further benefit the sustainability of 3D printing. Additionally, we see a tendency toward recyclable and bio derivative materials, which are more environmentally friendly. By 2023, service providers must use technologies to make these good effects more quantifiable.

Overall, the sustainability advantages will also satisfy the needs of end users who are starting to expect sustainable products, as shown, for instance, by the present “Right to Repair” campaign, which asks for repairable goods and spare parts throughout the duration of products.

A growing trend is 3D printing metal.

In 2023, we anticipate a significant rise in the usage of metal 3D printing when examining material and technological developments. In comparison to conventional manufacturing, this makes it possible to produce intricate metal components with a great deal less waste and for less money. The market for metal polymers in particular has emerged and will expand in 2023. This provides the chance to use filaments to create metal pieces. Metal and polymer particles are present in the filaments, but the polymer particles are eliminated from the component during the debinding and sintering steps that take place after printing. Currently, using metal filaments to print things has design restrictions and is only practical for tiny parts with simple designs. However, particularly from a price standpoint, metallic filaments are a very excellent alternative to conventional metal AM technologies like SLM for appropriate items.

We at Replique have previously used the technology, working with Alstom, a pioneer in green and intelligent transportation, among other things. Here, we have built a visible metal component that is certified for additive serial production for the first time. The pieces are produced quickly and affordably utilising metal FDM technology using Ultrafuse 316L stainless steel.

Conclusion: A look at 3D printing in the future

We are certain that 3D printing will have a favourable impact on the global manufacturing market in 2023, with enhanced sustainability, robustness, and lower prices. To really achieve industrial rank, however, established methods and ensured quality are required, as well as techniques to monitor and manage print quality. To do this, we see a significant tendency toward digital procedures that link and simplify every activity from choosing, storing, purchasing, and monitoring items through 3D printing.